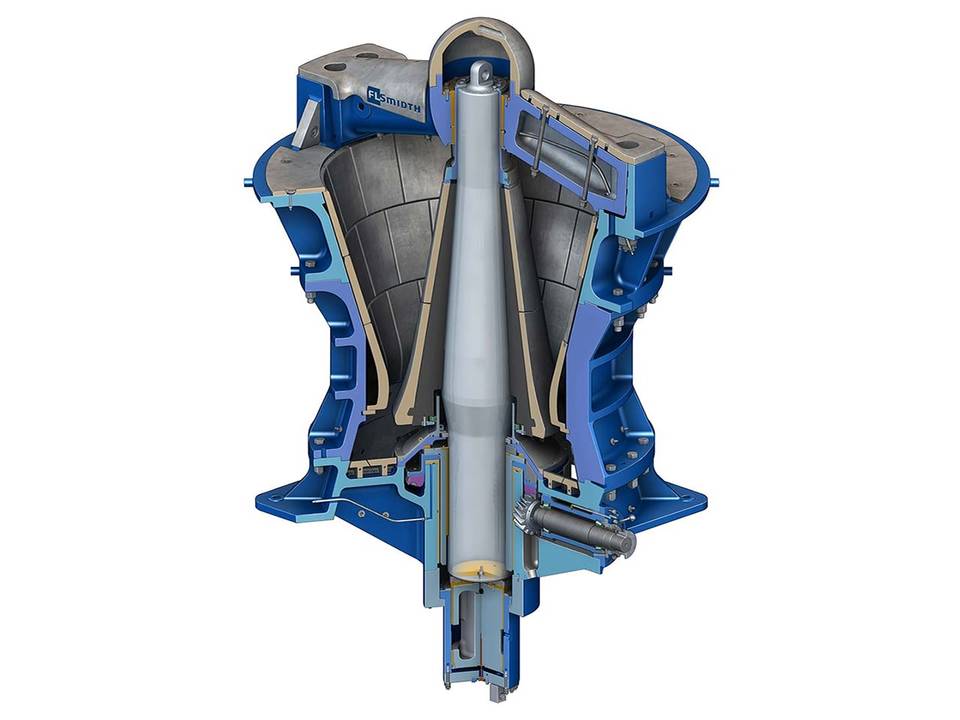

Gyratory Crusher - Preventative Maintenance

On-demand

On-demand

Enjoy higher power motor and matching drivetrain without having to move into a larger size crusher. Improve the operational efficiency and scheduled maintenance practices of your Gyratory Crusher. In this webinar you will increase your knowledge and understating of critical settings that will lead to improved productivity. In this webinar you will learn:

With 16+ years in the mining industry and 10 years as FLSmidth’s Technical Specialist in crushing equipment, Matthew has been and currently is involved in customer support and product line development in all aspects of crushing equipment. His experience ranges from field support to improvement concepts in mechanical & automation design, functional ability to training development and roll out. He has trained clients across the globe and internal employees including the team of crushing field engineers he manages.

With over 18 years of management experience related to hands-on mill design & construction experience, mining & mineral processing, supply & equipment procurement, expediting, and personnel scheduling. Charles has also acquired intimate knowledge of the commissioning and startup of multiple types of equipment. He began his career with FLSmidth, Inc in 2012 as a Global Project Manager supporting the Operations & Maintenance group and has supported FLSmidth’s Material Handling division as their Field Operations Manager.